Stamping is mainly for different specifications of the copper belt stamping. Other products have different stamping and formation processes, primarily divided into three categories: button surface stamping, stretching stamping, and miscellaneous items. Button surface stamping and drawing stamping copper buttons were the birth of the original process, the first step of the birth of copper buttons, the most conventional but critical part.

冲压,主要是对不同规格的铜带进行冲压,不同产品有不同的冲压工艺和形成过程,主要分为钮面冲压、拉伸冲压和杂件三大类。而钮面冲压和拉伸冲压是一个铜质扣钮诞生的最初工艺,是铜质钮扣诞生的第一步,最常规,同时也是最关键的部分。

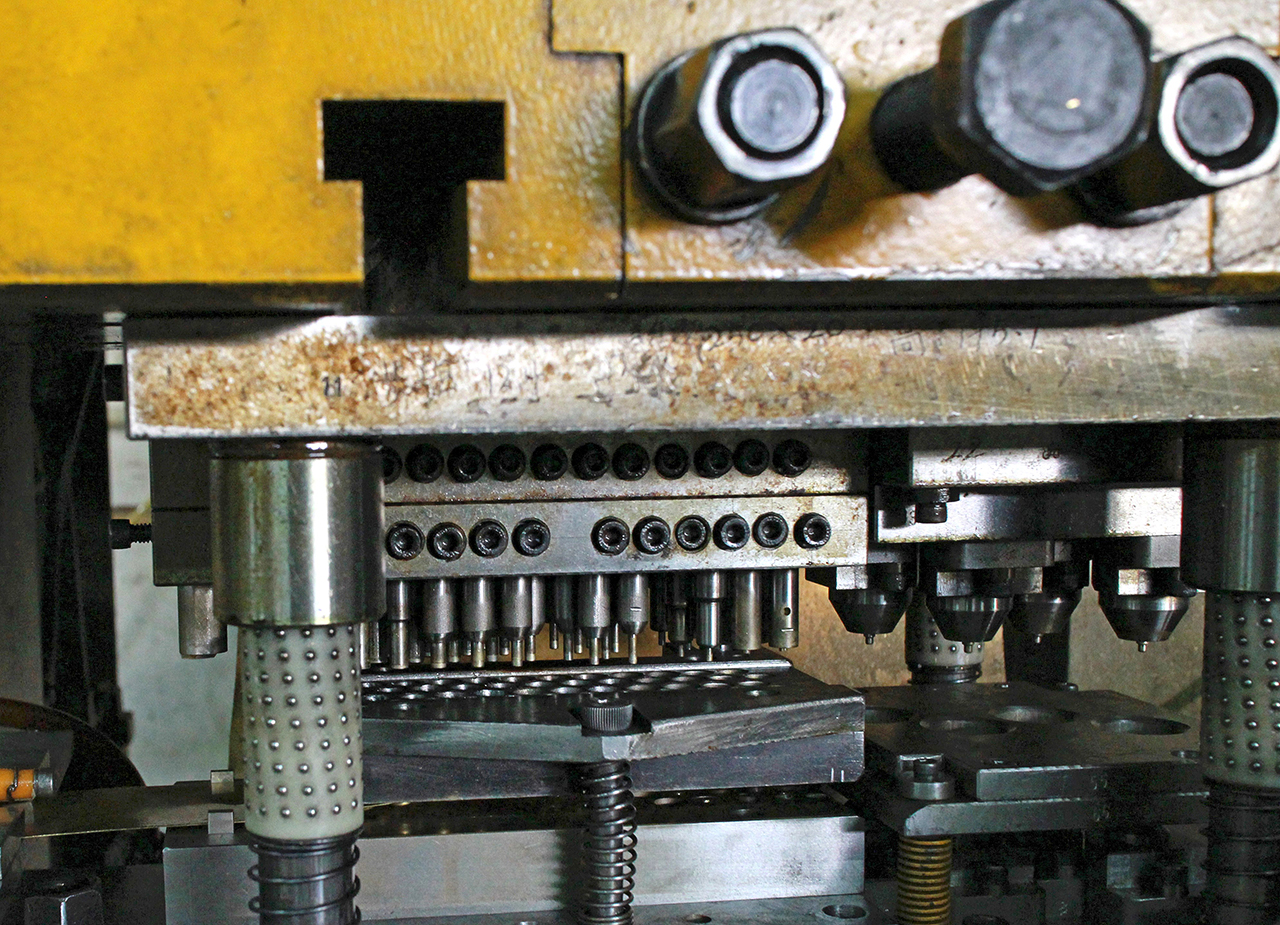

Button Cap Stamping: various conventional buttons in the face stamping process; the button surface only needs to cut back pressure type, molding, and one-step. Button surface stamping is generally “one out of one” to “one out of three”; a machine installed 1~3 die and 1~3 die, one pressure type out 1~3 button surface. “One out of two” or “one out of three” inefficiency is better than “one out of one,” but in the stability of “one out” more advantages, according to the production process and requirements of specific products, choosing different stamping methods to ensure the output, while the quality of stamping product stability.

钮面冲压:就是各种常规钮扣的面件冲压工艺,钮面只需剪口后压型,一次成型,一步到位。钮面冲压一般是“一出一”到“一出三”,即一台机器装1~3个剪口模和1~3个压型模,一次压型出来1~3个钮面。“一出二”、“一出三”在效率上优于“一出一”,但在稳定性上“一出一”更具有优势,根据具体产品的生产工艺和要求,选择不同的冲压方式,保障产量的同时,兼顾冲压产品质量的稳定性。

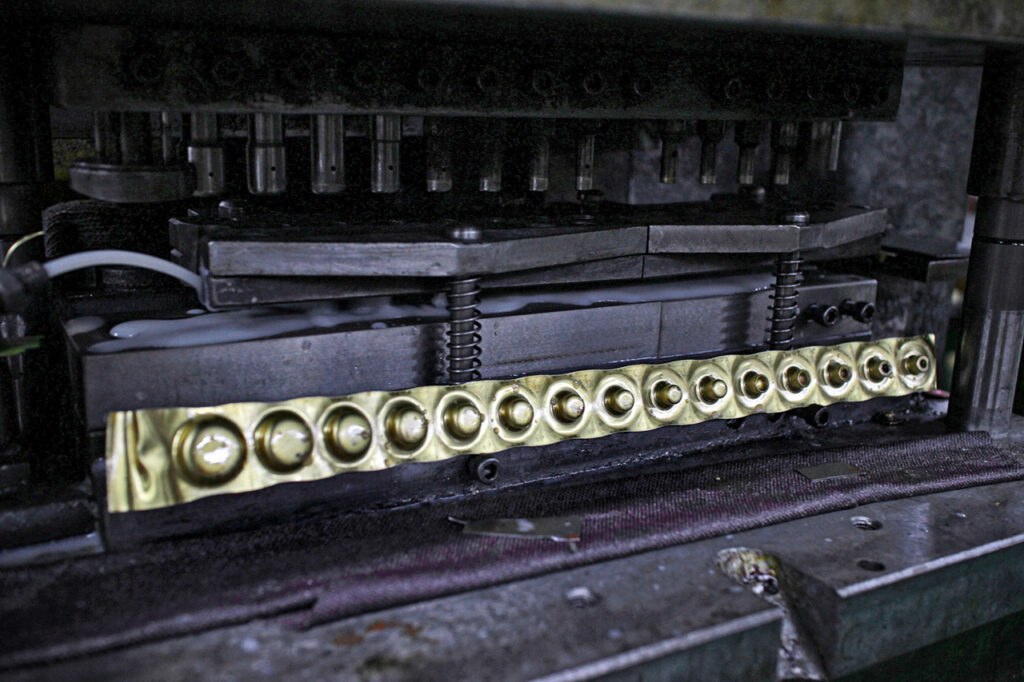

Drawing Stamping: Generally, it cannot be done in one step; it needs several stretches to form the button surface or the bottom shell, and it often needs to pull the process to achieve the goal. In the process of stretching, each drawing die is in a step-by-step stretch forming a stretching die process of stretching, such as the standard single/double prong bottom, with the core-shell, as well as a single prong, even one-piece button, is in after stretching, gradually formed. Some even need to 11~12 the tension, the 2~3 machine simultaneously, the final can be formed, and then the pressure type cut mouth becomes a black embryo product. La Chong pressure is generally “one out, one” and “one out of two” two stamping modes, “one out of a” broader scope of application, “one out of two” more efficient, in the production of different products, the formulation of reasonable production arrangements.

拉伸冲压:凡是无法一步到位,需要多个拉伸环节才能成形的钮面或底壳,往往需要通过拉伸工艺来达到目的。在拉伸的过程中,每一个拉伸模都是在一步步的拉伸成形,一个拉伸模即为一个拉伸变化的过程,例如常见的单针/双针底壳、配胶芯的底壳,以及弹弓、连底工字钮等,都是在经过一次次拉伸后,渐渐成型的。有些甚至需要11~12次的拉伸,2~3台机器同时运作,最终才能成形、再压型、剪口,成为一个黑胚产品。拉伸冲压一般是“一出一”和“一出二”两种冲压模式,“一出一”适用范围更广,“一出二”效率更高,在生产上针对不同产品,制定合理的生产安排。

Miscellaneous items: Miscellaneous items include D-button, gourd buckle, word folder, trousers buckle, tail folder, and other production items. Stamping of large machines is relatively stable; in stamping, different products need to replace different molds, the need to replace more molds, which produces more labor costs and longer consumption time. As a result of using manual and time-consuming stretching molds, the button surface stamping is faster. Stamping machine by professionals in each use of the machine before the quality inspection and commissioning, and in the stamping process to the pressure of the product sampling. Because of the relative stability of large machines, the machine operation by the machine staff “one person multiple machines” to supervise machine stamping products quantity, quality double supervision, to ensure efficient production. Large machines in stamping is a delicate process, significantly when the pressure type, an impurity, or a bead of water … can affect the shape of the product appearance, so the machine cleaning and workshop environment are also vital parts.

杂件:杂件多为D字扣、葫芦扣、又字夹、裤扣、尾夹等的生产。

冲压用的大型机器都相对稳定,在冲压不同产品时需更换不同的模具,需要更换的模具越多,其中产生的人工成本也就越多,消耗的时间也就越长。由于拉伸使用的模具较多,所以在人工和耗时等方面,钮面冲压更省更快。冲压机器由专业人员在每次使用机器之前进行质检和调试,并在冲压过程中对冲压的产品进行抽检。由于大型机器相对稳定,所以机器运作时,由看机人员“一人多机”对监管机器冲压的产品进行数量、质量的双重监管,保证生产的高效。大型机器在冲压时是一个精细化的过程,特别是在压型的时候,一粒杂质、一颗水珠……都能影响到产品外观的成型,所以机器的清洁及车间的环境也是至关重要的一部分。

Dot-gas for the relative stability of stamping machines, before stamping products to take the first out of the black embryo model effect and the assembly of the Black embryo, the final confirmation of the black embryo products with no problem, and then began stamping products, to eliminate hidden dangers at the source. In the stamping process, we have a professional QC during the stamping period of irregular sampling of product quality, supervision of product quality stability, and the quality of the production of Gram embryo in the first place, lest the late detection of problems results in more losses.

DOT-GAS针对冲压机器的相对稳定性,在冲压产品之前采取先出黑胚样板效果,并装配黑胚,最终确认黑胚产品没问题之后,再开始冲压产品大货,以此来在源头上杜绝隐患。在冲压过程中,我们有专业QC在冲压期间不定时的抽检产品质量,监管产品质量的稳定性,把克胚生产的质量放在第一位,以免在后期发现问题时,造成更多的损失。

Written by Lynne Lee

Re-edited by Ricky, h.k. Poon / Photography by KL

Copyright Notice: The text content belongs to Dot-gas Intl Co.; Any form of reprint and use for commercial or non-commercial purposes is prohibited.

版权声明: 文字内容归Dot-Gas公司拥有; 不允许任何形式的转载及使用于任何商业或非商业用途。