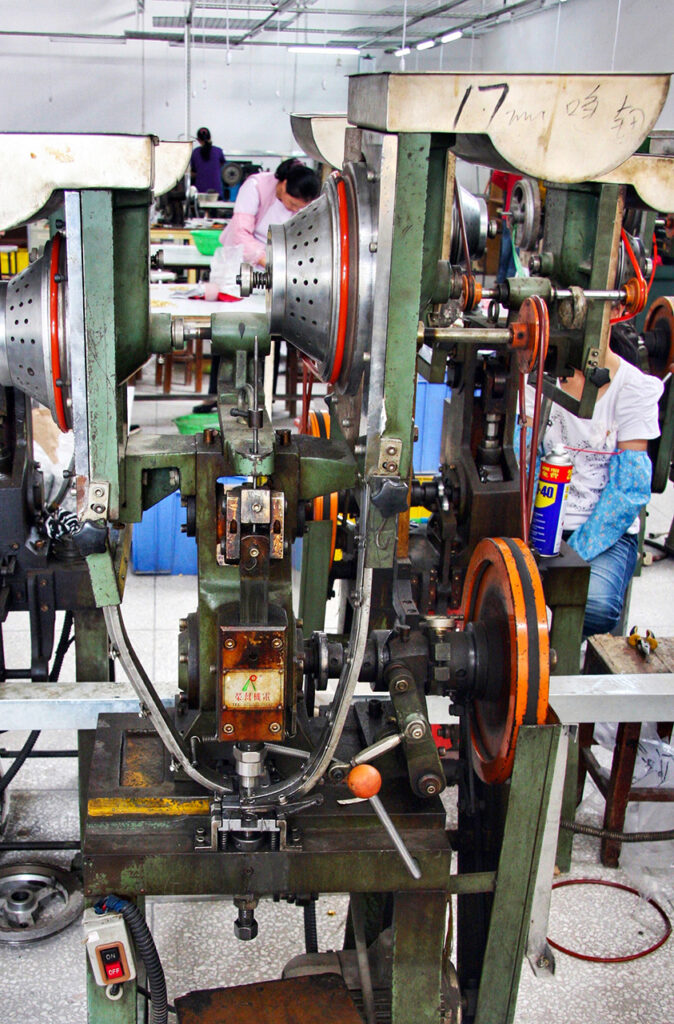

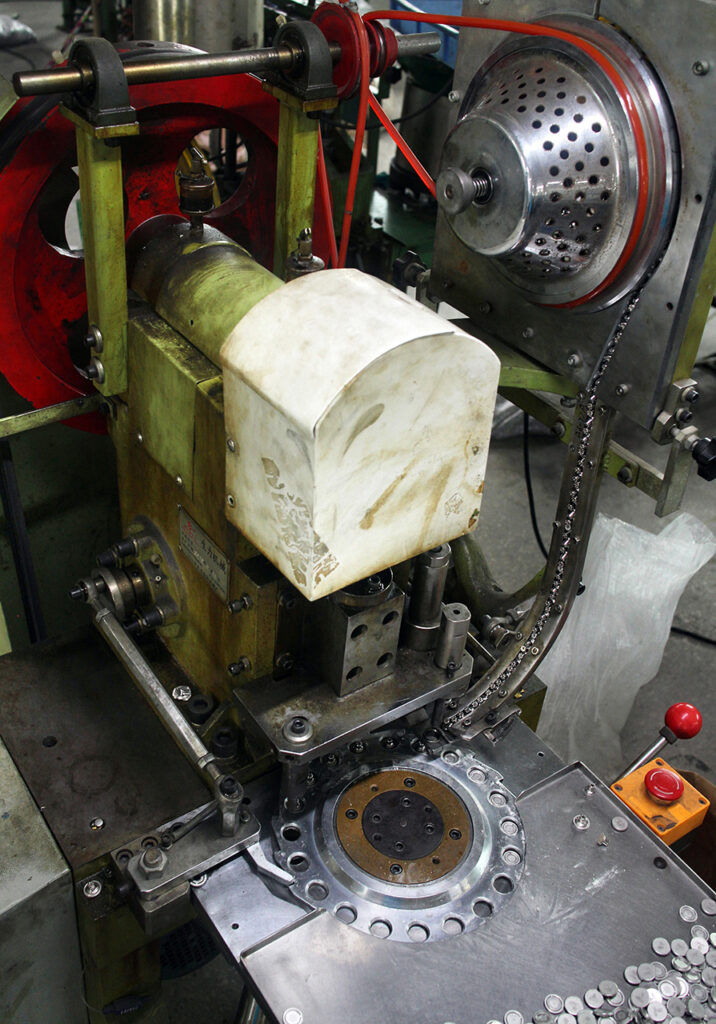

The Automatic Assembly Machine is mainly for brass-made button assembly. (1) Stable base. The four-foot iron frame base is safe and firm, enhancing body balance. (2) Vibrating feed. Numerical control of feed vibration intensity, scientific stability, and reduced card material. (3) Intelligent monitoring. There is no material in the card material other than the handbrake; there are intelligent monitors. It can be the first time an automatic shutdown, timely stop loss, reduced loss, or adequate protection of production rate. (4) digital amplitude modulation. The digital control vibration amplitude reasonably controls the assembly to feed the material speed, does not block the material, and reduces the product attrition degree. (5) Manual pressure adjustment. Manual debugging assembly Force and detection, one step, can accurately ensure that each button in the assembly is combined with pressure to maintain consistency so that the production has excellent stability. Look at the machine personnel use fully automatic assembly, the general use of “one person multiple machine” modes of care, the average person to take care of 2-3 sets of assembly machine, timely Tim material, and non-stop patrol-type supervision and sampling between the different machines.

全自动冧口机:全自动冧口机主要是针对铜质材料钮扣产品的冧合。(1)底座稳固。四脚式铁架底座,安全牢固,提高机体平衡性。(2)震动送料。数值调控送料的震动强度,科学稳定,减少卡料。(3)智能监测。在卡料、无料时除了手闸,还有智能监测器。它能第一时间自动停机,及时止损,降低损耗,有效保障出品率。(4)数字调振幅。数字调控震动幅度,合理控制冧合送料速度,不堵料,降低产品磨损程度。(5)手动调压。人工调试冧合力并检测,一步到位,能精准确保每一粒钮扣在冧合过程中的冧合压力保持一致,使出品具有优良的稳定性。看机人员使用全自动冧口机时,一般采用“一人多机”看管模式,每人平均看管2-3台冧口机,及时添料,并在不同机器之间不间断的巡逻式监管及抽检。

Semi-automatic Assembly Machine is dedicated to the use of alloy buttons, “One person, one machine” mode of work, the average output per hour about 3000~4000pcs, manually placed alloy button surface (surface parts), assembly machine automatic feeding (bottom), assembly, and finally formed. Semi-automatic assembly machines with automatic assembly machine base solid, digital amplitude, and manual pressure adjustment of the same point; the difference is that semi-automatic assembly machines without intelligent monitoring, only handbrake, can manually suspend operation in the assembly process, adjust the card material, add materials and so on. At the same time, the “one person, one machine” mode of operation occupies more labor costs, but in the supervision of more than “one person multiple machines,” more convenient and timely loss. In addition, the machine assembly process, the artificial continuous display surface parts, cannot consider the product assembly quality sampling.

半自动冧口机:半自动冧口机是专门针对合金钮扣而采用的“一人一机”工作模式,平均每小时产量约3000~4000pcs,由人工手动摆放合金钮面(面件)后,冧口机自动送料(底件)、冧合,最终成型。半自动冧口机具有全自动冧口机底座稳固、数字调振幅和手动调压的相同点,不同之处在于半自动冧口机没有智能监控,只有手闸,可手动在冧合过程中暂停运行,调整卡料、添加物料等。同时“一人一机”操作模式占用较多的人工成本,但在监管方面比“一人多机”更方便,止损更及时。另外,机器冧合过程中,人工持续摆放面件,无法兼顾产品冧合质量的抽检。

Manual Assembly is completed by the assembly personnel and manual operation of the assembly machine production; each button is in the hand of the assembly staff, and the average output per hour is about 2000~3000pcs. (1) The body is fixed. The machine is fixed, and the personnel are assembled by hand. (2) assembly sampling before closing. Assembly personnel in the display of surface parts, the bottom part of the inspection of products, timely elimination of defective products, reduce the probability of faulty goods will further minimize loss. (3) assembly of the process of quality inspection. Assembly staff for each assembled button are in the quality inspection, found assembly with problems, assembly and wrong, immediately pick out. The whole artificial assembly is superior to the automatic assembly machine and the semi-automatic assembly machine in the quality control aspect but is in the inferior position in the output; the labor cost is high. In addition, because it is a manual operation assembly, the product assembly force is relatively unstable, and the same batch of products has slight differences in appearance. Dot-gas according to different orders, different orders, different customer needs, and so on to develop a scientific assembly plan and determine the final assembly method. There is no best way to assemble it; it is only the most suitable way.

Dot-gas is committed to providing better solutions to make products more stable in assembly. For example, in the complete manual assembly, we provide dedicated mold services to improve product quality and enhance the stability of the artificial assembly process while effectively controlling the rate of defective products. Not only that, we are also in the fully automatic assembly mode, in quality control and production quality to provide “special plane” services, strict checks, exceptional QC, select each button, and the production quality in the first place.

全人工冧口:全人工冧口是完全由装配人员摆放及手动操作冧合机器的生产方式,每一粒钮扣都出自装配人员之手,平均每小时产量约2000~3000pcs。(1)机体固定。冧合机器固定,装配人员手动冧合受力时稳固。(2)冧合前抽检。装配人员在摆放面件、底件的同时检查产品,及时剔除不良品,降低不良品概率,将损耗也进一步减少。(3)冧合过程中质检。装配人员每冧合一粒钮扣都是在做质检,发现冧合有问题的、冧合坏的,即刻挑出。全人工冧口在质量监控方面优于全自动冧口机和半自动冧口机,但在产量上处于劣势,人工成本高。另外,由于是手动操作冧合,所以产品的冧合力相对来说并不稳定,同批产品在外观上存在细微差异。

DOT-GAS根据不同订单、不同订单量、不同客户需求等来制定科学的装配方案并决定最终装配方式。没有最好的装配方式,只有最合适的装配方式。DOT-GAS致力于提供更好的解决方案,使产品在装配过程中品质更加稳定。例如,在全人工装配上我们提供专用模的服务,来提高产品质量,并增强人工冧合过程中的稳定性,同时有效控制不良品率。不仅如此,我们还在全自动冧合模式中,在品质监控及出品质量方面提供“专人专机”服务,严格把关,专人QC,精选每一粒钮扣,把出品的品质放在第一位。

Written by Lynne Lee

Re-edited by Ricky, h.k. Poon / Photography by KL

Copyright Notice: The text content belongs to Dot-gas Intl Co.; Any form of reprint and use for commercial or non-commercial purposes is prohibited.

版权声明: 文字内容归Dot-Gas公司拥有; 不允许任何形式的转载及使用于任何商业或非商业用途。